by Robert B. Corbett, DVM, PAS, DIPL. ACAN

Milk replacers come in a wide variety of protein and fat concentrations. The type and quality of the ingredients also vary greatly. In order to determine the quality of a milk replacer, the dairy owner must become familiar with the ingredients and guaranteed analysis listed on the milk replacer.

Both the percent of protein in the milk replacer and its source must be evaluated before one can determine its quality. Most milk replacers contain 20 to 28% protein with the major portion of the protein being derived from milk products or by-products of the milk processing industry. These would include dried skim milk, sodium caseinate, whey protein concentrate, dried whole whey, delactosed whey, dried buttermilk and milk albumin.

In the past, dried skim milk was used as the major source of protein in calf milk replacers. When the demand for skim milk for human consumption increased significantly, whey protein concentrate was used to replace a major portion of the protein previously supplied by skim milk. Currently, the price of skim milk protein and whey protein varies to the point where it may be more economical to use one over the other. The major difference between the two is that skim milk protein contains casein and whey protein does not. Skim milk protein will form a curd in the abomasum and whey protein will not. However, multiple studies have not shown any significant difference in the performance of calves regardless of which of these two milk protein sources were used. Milk proteins contain the highest quality protein and are more easily digested than other protein sources.

In an effort to reduce the cost of milk replacers, most manufacturers will offer products that substitute some of the milk-based protein with vegetable protein. Commonly used proteins would be soy proteins and hydrolyzed (soluble) wheat gluten protein (SWGP).

Soy proteins are often used in less expensive calf milk replacers. Unprocessed soy proteins contain numerous anti-nutritional factors (ANF). These ANF interfere with normal enzyme function and can bind to specific sugars or glyco-proteins, which result in decreased absorption of nutrients and damage to the gut wall. Soy proteins have also been shown to produce a marked allergic reaction in the gut, which may result in damage to the microvilli that line the small intestine. As a result, most milk replacer manufacturers that include soy proteins in their products will utilize soy proteins that have been processed in a manner which eliminates the majority of the problems previously stated.

The soy proteins used in milk replacers most commonly are soy flour, soy protein concentrate, and soy protein isolate. All three products are obtained from defatted soy flakes through different processes. Soy flour is obtained simply by grinding the soy flakes. The protein in soy flour is the least utilizable of the three products but may be improved slightly through a heat treatment process. Soy protein concentrate and soy protein isolate are obtained through different chemical processes and are more available to the animal than the soy flour.

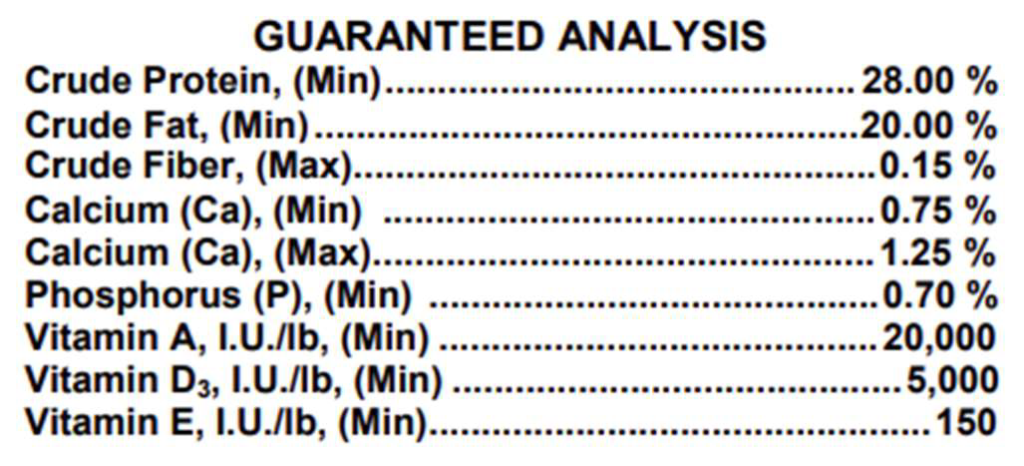

The calf cannot utilize soy proteins very well during the first 2 to 3 weeks of life. Therefore, milk replacers that contain soy protein should not be fed to calves younger than 3 weeks of age. Some of the manufacturers have tried to disguise soy protein on their label by calling it Glycine max, which is the scientific name for the soybean. Other companies have tried to use fiber levels to prove the quality of their product. A fiber level of 0.15 has been used to implicate a high-quality milk replacer with all of the protein being derived from milk products. However, soy protein isolate carries no fiber with it and thus invalidates the assumption that a milk replacer with a 0.15 fiber level contains all milk protein. Other protein sources such as blood, plasma, and albumin are less available than milk protein and contain no fiber. Also, the method of analyzing the fiber content of a milk replacer is not extremely accurate, and therefore should not be accepted totally at its face value.

Wheat gluten protein is one of the largest proteins in nature. This makes it very difficult for the milk-fed calf to be able to digest and absorb this protein. It is also not soluble in water and therefore would not stay in suspension if used as a protein source in milk replacers. However, wheat gluten protein can be processed using enzyme hydrolysis to produce hydrolyzed (soluble) wheat gluten protein (SWGP). This process breaks down the large protein into smaller segments that are more easily digested and absorbed as well as being more soluble and able to remain in suspension when mixed with water. If the process of enzyme hydrolysis is allowed to continue beyond the optimal point in time, the product becomes bitter and less palatable. If the process is carried out for an insufficient amount of time, the proteins will be less digestible and remain unsoluble in milk replacer. SWGP has a different amino acid profile than milk proteins. It is much lower in lysine and contains less threonine than milk proteins. For this reason, these amino acids should be added to milk replacers to improve the amino acid profile when using SWGP as a protein source. It is generally recommended that SWGP should not exceed 5% of the total milk replacer. This would replace approximately 20% of the milk-based protein.

There have been several trials evaluating the use of SWGP in milk replacers with varying results. The general consensus is that if using a high-quality SWGP in the formula, it will perform quite well when compared to an all-milk protein product. However, it would still be preferable to use an all-milk protein product in calves less than 3 weeks of age.

One of the ways to reduce the cost of the milk replacer is to increase the amount of vegetable protein in the formula. However, the label on the milk replacer bag does not stipulate what the exact percentage of vegetable protein that is contained in that product. The labels of two competitive products may look almost the same but vary in price significantly just because there is a higher percentage of vegetable protein in the cheaper product. This makes it very difficult for the dairy owner to make a well-informed decision on which product to purchase. The preference is usually to purchase the less-expensive product, not knowing that it might contain a higher percentage of vegetable protein. If in doubt, a reputable milk replacer manufacturer should be willing to disclose the percentage of vegetable protein that is contained in their products.

Another source of protein in milk replacer is bovine plasma protein. It is not as common as the vegetable protein sources since the cost of it is very similar to milk-based proteins. Some reports have suggested that the health of the calf is improved since it contains immunoglobulins, but the studies are not conclusive. The recommended level of inclusion is about the same as vegetable protein which is around 5% of the milk replacer formula. Bovine plasma has a lower level of the amino acid isoleucine, so milk replacer formulas containing bovine plasma should be supplemented with isoleucine.

There has been a tremendous amount of research in the last 10-15 years on the nutrition of the milk-fed calf. There has been a general trend to move away from products that contain vegetable proteins and to use products which are defined as being “all milk”. Most veterinarians and nutritionists are in agreement that using a high quality “all milk” milk replacer will provide the best results for the health and growth of dairy calves.

The fat level in most milk replacers generally varies from 18 to 22%. Some milk replacers have been formulated more recently to contain fat levels as high as 33%. It is important to keep in mind that Holstein milk is 26-28% protein and 30-32% fat on a dry matter basis. The source of fat is usually tallow or lard. In order for these fats to be easily mixed in water, and be more easily digested, they are homogenized and emulsified during the manufacturing process. Emulsifiers such as mono and diglycerides and lecithin are often added to aid in this process.

In addition to the fats being emulsified, they may also undergo an agglomeration process. This increases the surface area of small fat particles thus allowing them to be easier to mix into water and to stay in suspension once mixed. This process is often referred to as “instantized”. This process adds some cost to the milk replacer, so it is often optional.

Fat digestion is complex, but the most important enzyme involved in fat digestion is lipase. There are several management procedures that result in an increase in the amount of lipase produced by the calf. The first is the ingestion of adequate amounts of colostrum immediately after birth. This results in higher amounts of lipase being excreted into the gastrointestinal tract. Interestingly, this increased amount of lipase persists through weaning and beyond. The second factor is utilizing a nipple to feed milk to the calf. Saliva is an important source of lipase, and nipple-fed calves produce 3 times more saliva than bucket-fed calves. The other main source of lipase is the pancreas, but maximum pancreatic lipase secretion does not occur until the calf is 8 days of age. The calf depends heavily on salivary lipase the first 8 days of life so using a nipple at least during this time period will significantly enhance fat digestion.

Some of the main fat source may be replaced with a source of short-chained fatty acids such as coconut oil. Lipase is more efficient in the digestion of short-chained fatty acids resulting in enhanced fat utilization. Replacing 20% of the animal fat with coconut oil gives a fatty acid profile that is more similar to that of whole milk. The addition of coconut oil or other sources of short-chained fatty acids depends mainly on the cost of these products.

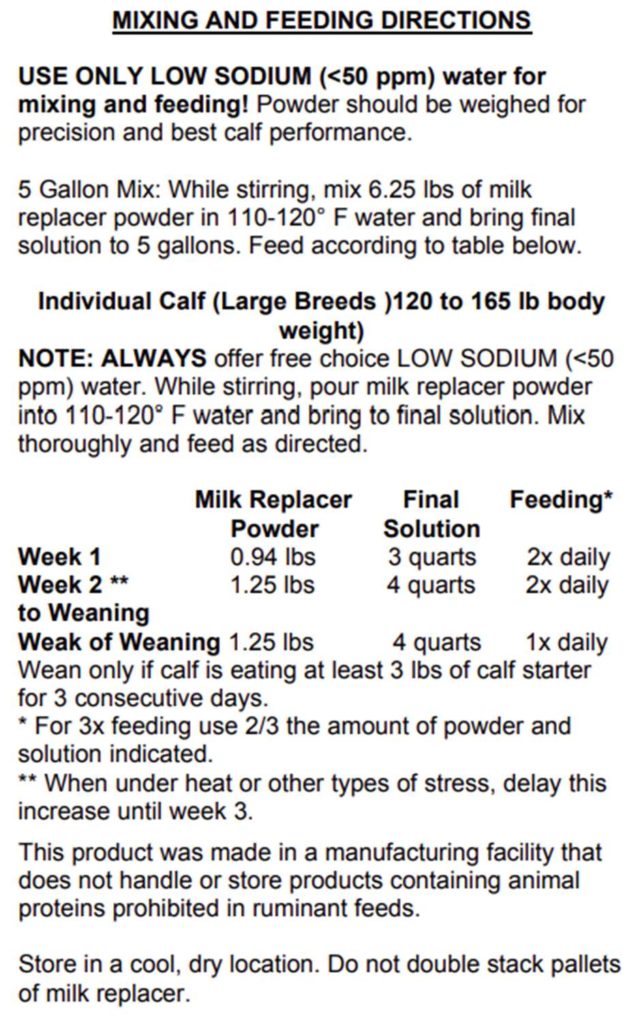

Calves less than 3 weeks of age can adequately digest up to 2.5 grams per pound of body weight per day of a high-quality fat source. If a newborn calf weighing 80 lbs. is fed a 20:20 milk replacer mixed at a rate of 1 pound per gallon and fed 2 quarts twice per day, it would receive 0.2 lbs. (90.8 grams) of fat per day. This is less than half of the amount that it can adequately digest (2.5 grams/lb. X 80 lbs. = 200 grams).

Even though this mixing rate and feeding rate is commonly used for young calves, it is obvious that this amount does not provide the nutrients needed to maximize the genetic potential for growth of the young dairy calf.

Lactose is the main carbohydrate added to milk replacers since it is a naturally occurring sugar in milk and is efficiently digested, especially by younger calves less than 3 weeks of age. Recent research has suggested that glucose (dextrose) can replace some of the lactose in milk replacers. Lactose concentration in milk replacers is rarely discussed, and most dairymen are unaware of its importance. Lactose plays an important role in the osmolality of the milk replacer. Osmolality is defined as the number of solute particles in a kilogram of solvent. In simpler terms, it is basically the concentration or amount of particles in a solution. If the osmolality is too high, then it will cause fluid to cross the intestinal wall into the lumen of the intestine to reduce the concentration of particles to a more physiological level. This will result in diarrhea.

The percent lactose in milk or milk replacer can roughly be calculated by subtracting the amount of protein, fat, and ash (mainly minerals) from the total amount of solids. The amount of lactose in whole milk is approximately 30%. However, the amount of lactose in a 20:20 milk replacer is approximately 48%. This is a 60% increase in the amount of lactose. This has a profound effect on the osmolality of the milk replacer. If the percent solids is increased as well, then the total amount of lactose consumed per day is also increased. The enzyme lactase is necessary to digest lactose. The total amount of lactase can be overwhelmed by the amount of lactose entering the GI tract. With an insufficient amount of lactase produced to digest the extra lactose consumed, a significant amount of lactose will pass into the large intestine undigested, resulting in hind gut fermentation of lactose.

The higher the percent protein and fat in milk replacer, the lower the percent lactose. The milk replacer formulas that contain more protein and fat come closer to achieving the normal amounts of these nutrients found in whole milk and have lower amounts of lactose, thus decreasing the chances of developing diarrhea due to high osmolality.

Newborn calves have little to no reserves of vitamins A, D and E. Good quality colostrum has high levels of these vitamins and can provide adequate levels to the calf provided she has received sufficient colostrum. Good quality milk replacers should also contain vitamins A, D and E in the appropriate levels which range from 10,000 to 30,000 USP Units of vitamin A per pound of milk replacer, 2,000 to 6,000 international units of vitamin D3 per pound, and 25 to 125 international units of vitamin E per pound. Some replacers also contain vitamin C since it seems to boost the immune response along with vitamin E.

Even though cow’s milk contains a fairly high level of calcium, milk replacer should be supplemented with a calcium source since the fat interferes with calcium digestibility. Iron should also be supplemented since the iron content of whole milk is low.

Most milk replacer manufacturers provide the option of medicating the product with DeccoxR or BovatecR (lasalocid) for the prevention and control of coccidiosis. It is advisable to use the same product in the milk replacer that you will be using in the calf starter if possible.

There are many ingredients that must be purchased from other manufacturers that are important in the formulation of a high-quality milk replacer. Many of the more reputable milk replacer manufacturers have their own quality control laboratories with stringent requirements in place to ensure that the products they produce are of the highest quality. These laboratories have two main goals when it comes to the products they are purchasing for inclusion into their milk replacers. One is to find out with company or companies meet their qualifications for that particular product, and second is to test the product to make sure it is up to their standards. If a product is found not to meet their qualifications, it is rejected. Where does this product end up?

It is a well-known fact that there are milk replacer manufacturers that always seem to have a lower priced product with the same protein and fat content compared to other companies. How can these companies make a profit by selling their product at a price significantly lower than other companies? One way is to purchase these ingredients that do not meet the quality standards of other more reputable companies. These less expensive products often do not stay in suspension as well, have lower digestibility and often result in poor performance. It is common to see an increase in health issues such as diarrhea and abomasal bloat when switching from a high-quality milk replacer to a lower quality product.

Ease of mixing and the ability to remain in suspension are two important things to consider in the quality of a milk replacer. The percent solids should remain the same from the first bottle to the last. The ability of a milk replacer to stay in suspension can be easily observed by pouring the recently mixed product into a glass cylinder and allowing it to sit for 30 minutes. A brix refractometer can also be used to determine the percent solids to see if there is a change over time.

When considering which milk replacer to buy, price is certainly an important consideration, but it should not be the only consideration. The overall quality of a milk replacer plays an important role in the average daily gain, efficiency of feed conversion, health of the calf, as well as future productivity. The economic emphasis should be placed on the cost per pound of gain, not the cost per calf per day.

This article was originally published by IBA Inc. in the September-October 2022 issue Dairy World and is reprinted with permission from Editor Jessica Belsito.