by Kelly Driver, MBA

Yes, dairy calves are affected by their own bovine-specific strain of coronavirus. This sickness can be a

significant cause of diarrhea (calf scours). Calf caregivers have been treating it for many years before the

novel coronavirus that causes COVID-19 emerged on the scene worldwide.

Is There a Connection?

In short, beyond the name, there is very little in common between the two strains because there are

many different versions of human and animal coronaviruses throughout the world. Each different

version of coronavirus has a very specific molecular makeup of the “spikes” on its surface. In order to

cause infection, these specific spike molecules must be able to attach to corresponding specific

molecules on a body cell, according to Dr. Russ Daly, South Dakota State University Extension

Veterinarian and Professor.

He further explains “pig cells have different surface molecules than do calf cells, than do human cells,

and so on. Additionally, respiratory cells have different surface molecules than do intestinal cells” (Daly,

2020). Calf caregivers may recall hearing about cats diagnosed with Feline Infectious Peritonitis (FIP) or

swine producers struggling with Porcine Epidemic Diarrhea (PED). These are all different forms of

coronaviruses (Daly, 2020).

Calf Scours

Scours is a term that the cattle industry has long used to refer to diarrhea in young calves. 95% of

infectious calf scours in calves under three weeks of age are caused by coronavirus, rotavirus or

Cryptosporidium (U of MN). All calves are exposed to these pathogens starting the very moment they

are born in the calving area. Whether a calf gets sick or not often depends on how much of the

pathogen the calf receives. The higher the dose of pathogen, the greater the risk of calf scours. So, let’s

take a quick look at the University of Minnesota’s description of these three contaminants:

-Rotavirus infects cells essential to the absorption of nutrients in the small intestine. The lack of small

intestine nutrient absorption causes nutritional deficiencies for the calf and interferes with the rest of

the digestive tract’s ability to absorb water. The result is diarrhea, with an added complication of

missing nutrients for the calf.

-Coronavirus infects cells in a similar way to rotavirus. However, instead of just interfering with

absorption, the virus actively kills cells in the lining of the intestine. The result is widespread destruction

of the lining of the small intestine. The calf cannot absorb any nutrients, the inflammation is massive,

and severe diarrhea occurs.

–Cryptosporidium, often referred to as ‘Crypto’, is a protozoan (a microscopic animal). The most

important thing to remember is that Crypto is not bacteria. Crypto implants itself in the wall of the

intestine and causes severe inflammatory damage to the lining of the intestine. This damage results in

diarrhea for the calf. Crypto infections are incredibly painful for the calf. Outside of the body, crypto has

a thick shell that allows it to survive for long periods in the environment (Source: University of Minnesota Extension).

Since Cryptosporidium was addressed in a previous Calf Corner blog, we will continue to

focus on the corona & rota viruses.

Rotaviruses are the most common cause of diarrhea in young calves, typically from 5-21 days of age.

Pale yellow diarrhea is common, and calf caregivers may also observe blood specks and mucus in the

feces. Affected calves are often lethargic, reluctant to drink, and have dull eyes.

One of the big challenges with rota and corona viruses is as the calves become dehydrated, they become

more susceptible to secondary infections.

Diagnosis

Proper diagnosis to determine the cause of calf diarrhea should be done with your herd veterinarian.

This may include fecal sampling at a diagnostic laboratory.

Treatment

Oral fluids are the most important treatment that should be started at the first signs of diarrhea to help

prevent the dehydration that ultimately kills calves. Allowing calves to drink the electrolytes themselves

is preferred, as oral fluids delivered by stomach tube may have delayed absorption because they are

deposited in the rumen. If the calf is already quite dehydrated, intravenous fluids should be given.

Please do NOT stop feeding milk to these calves. They need all the nutritional value they can get from

the milk to help fight off disease.

Scours is quite uncomfortable and painful for calves. Work with your veterinary to provide an approved

anti-inflammatory for pain relief as needed in your calf management protocol.

Taking the calf’s rectal temperature should be a standard part of any health assessment. Antibiotics are

another tool that should be addressed in calf protocols. Remember that 95% of calf scours under 3

weeks of age are caused by viruses and protozoans, not bacteria, rendering ineffective to treat the cause

of the disease. Therefore, antibiotics would normally be reserved for cases when the calf’s temperature

is outside normal range of 101-102.5 degrees Fahrenheit (U of MN).

Prevention

Prevention of calf scours all together is the real key.

Starting early with a solid vaccination program administered to a healthy cow helps to boost the

antibodies available to the calf in the four quarts of colostrum it should be fed within the first two hours

of life. Vaccines given at the correct times while the calf is still in utero can also target scours-causing

agents. There are also some products available that can reduce scours when given at birth to the calf.

The herd veterinarian can help develop a robust vaccination program tailored to each specific herd

situation.

I can’t emphasize how important it is that everything the newborn calf has contact with should be very

clean. From their arrival in a very clean, well-bedded calving area to well-managed, high-quality

colostrum that is low in bacteria, to properly clean and sanitized feeding equipment and housing, try to

look at every item your calves will come in contact with. The more pathogens that can be removed

through proper cleaning, the more we set our calves up for success.

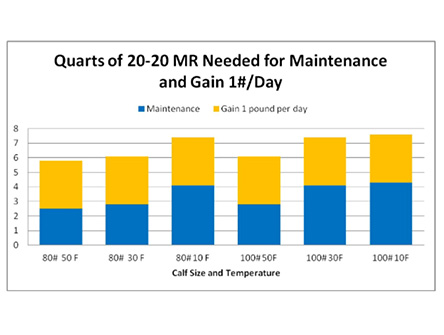

Another key in calf success is proper nutrition. Calves need a minimum of 8 quarts of either whole milk

or high-quality milk replacer each day to meet their maintenance and growth needs. Their need for

additional energy and nutrition increases anytime the temperature is outside their thermal neutral zone,

particularly when it is colder. (We can help keep calves warmer with a properly fitted calf jacket that

contains a true insulating material, like ThinsulateTM.) Delivering calves ample nutrition with a consistent

temperature, total solids level and on a routine time schedule also aids in prevention.

Housing units, whether individual or group, should be cleaned and disinfected between each use. Calf-Tel offers many plastic feeding and housing options that are designed for easy clean up and can be

viewed at Calf-Tel.com.

All of these factors can be combined to best prevent calf scours. Remember that rotaviruses,

coronaviruses and Cryptosporidium naturally exist on dairy farms. It is our job as the calf caregivers to

limit each newborn calf’s exposure level to these threats. Using a farm-wide approach that includes total

herd health under supervision from a veterinarian, high-quality colostrum management and calf

nutrition, and cleaning and sanitizing all feeding equipment and housing areas gives the best chance of

limiting calf scours events.

Kelly Driver, MBA has been involved in the New York dairy industry all her life. In addition to raising dairy

calves and replacement heifers, she is the Eastern US & Canada Territory Manager for Calf-Tel. Feel free

to contact her at kellydriver@hampelcorp.com with your calf questions or suggest a topic you would like

addressed in a future blog.

Sources:

Armstrong, Joe, DVM. (2019). Causes and prevention of dairy calf scours. University of Minnesota

Extension. Retrieved from Causes and prevention of dairy calf scours | UMN Extension.

Daly, Russ. (2020, September 9). COVID-19 and Livestock: Is there a connection? South Dakota State

University Extension. Retrieved from COVID-19 and Livestock: Is there a connection? (sdstate.edu).

Keha A, Xue L, Yan S, Yue H, Tang C. Prevalence of a novel bovine coronavirus strain with a recombinant

hemagglutinin/esterase gene in dairy calves in China. Transbound Emerg Dis. 2019 Sep;66(5):1971-1981.

doi: 10.1111/tbed.13228. Epub 2019 May 31. PMID: 31077561; PMCID: PMC7168545.

by Kelly Driver, MBA

Yes, dairy calves are affected by their own bovine-specific strain of coronavirus. This sickness can be a

significant cause of diarrhea (calf scours). Calf caregivers have been treating it for many years before the

novel coronavirus that causes COVID-19 emerged on the scene worldwide.

Is There a Connection?

In short, beyond the name, there is very little in common between the two strains because there are

many different versions of human and animal coronaviruses throughout the world. Each different

version of coronavirus has a very specific molecular makeup of the “spikes” on its surface. In order to

cause infection, these specific spike molecules must be able to attach to corresponding specific

molecules on a body cell, according to Dr. Russ Daly, South Dakota State University Extension

Veterinarian and Professor.

He further explains “pig cells have different surface molecules than do calf cells, than do human cells,

and so on. Additionally, respiratory cells have different surface molecules than do intestinal cells” (Daly,

2020). Calf caregivers may recall hearing about cats diagnosed with Feline Infectious Peritonitis (FIP) or

swine producers struggling with Porcine Epidemic Diarrhea (PED). These are all different forms of

coronaviruses (Daly, 2020).

Calf Scours

Scours is a term that the cattle industry has long used to refer to diarrhea in young calves. 95% of

infectious calf scours in calves under three weeks of age are caused by coronavirus, rotavirus or

Cryptosporidium (U of MN). All calves are exposed to these pathogens starting the very moment they

are born in the calving area. Whether a calf gets sick or not often depends on how much of the

pathogen the calf receives. The higher the dose of pathogen, the greater the risk of calf scours. So, let’s

take a quick look at the University of Minnesota’s description of these three contaminants:

-Rotavirus infects cells essential to the absorption of nutrients in the small intestine. The lack of small

intestine nutrient absorption causes nutritional deficiencies for the calf and interferes with the rest of

the digestive tract’s ability to absorb water. The result is diarrhea, with an added complication of

missing nutrients for the calf.

-Coronavirus infects cells in a similar way to rotavirus. However, instead of just interfering with

absorption, the virus actively kills cells in the lining of the intestine. The result is widespread destruction

of the lining of the small intestine. The calf cannot absorb any nutrients, the inflammation is massive,

and severe diarrhea occurs.

–Cryptosporidium, often referred to as ‘Crypto’, is a protozoan (a microscopic animal). The most

important thing to remember is that Crypto is not bacteria. Crypto implants itself in the wall of the

intestine and causes severe inflammatory damage to the lining of the intestine. This damage results in

diarrhea for the calf. Crypto infections are incredibly painful for the calf. Outside of the body, crypto has

a thick shell that allows it to survive for long periods in the environment (Source: University of Minnesota Extension).

Since Cryptosporidium was addressed in a previous Calf Corner blog, we will continue to

focus on the corona & rota viruses.

Rotaviruses are the most common cause of diarrhea in young calves, typically from 5-21 days of age.

Pale yellow diarrhea is common, and calf caregivers may also observe blood specks and mucus in the

feces. Affected calves are often lethargic, reluctant to drink, and have dull eyes.

One of the big challenges with rota and corona viruses is as the calves become dehydrated, they become

more susceptible to secondary infections.

Diagnosis

Proper diagnosis to determine the cause of calf diarrhea should be done with your herd veterinarian.

This may include fecal sampling at a diagnostic laboratory.

Treatment

Oral fluids are the most important treatment that should be started at the first signs of diarrhea to help

prevent the dehydration that ultimately kills calves. Allowing calves to drink the electrolytes themselves

is preferred, as oral fluids delivered by stomach tube may have delayed absorption because they are

deposited in the rumen. If the calf is already quite dehydrated, intravenous fluids should be given.

Please do NOT stop feeding milk to these calves. They need all the nutritional value they can get from

the milk to help fight off disease.

Scours is quite uncomfortable and painful for calves. Work with your veterinary to provide an approved

anti-inflammatory for pain relief as needed in your calf management protocol.

Taking the calf’s rectal temperature should be a standard part of any health assessment. Antibiotics are

another tool that should be addressed in calf protocols. Remember that 95% of calf scours under 3

weeks of age are caused by viruses and protozoans, not bacteria, rendering ineffective to treat the cause

of the disease. Therefore, antibiotics would normally be reserved for cases when the calf’s temperature

is outside normal range of 101-102.5 degrees Fahrenheit (U of MN).

Prevention

Prevention of calf scours all together is the real key.

Starting early with a solid vaccination program administered to a healthy cow helps to boost the

antibodies available to the calf in the four quarts of colostrum it should be fed within the first two hours

of life. Vaccines given at the correct times while the calf is still in utero can also target scours-causing

agents. There are also some products available that can reduce scours when given at birth to the calf.

The herd veterinarian can help develop a robust vaccination program tailored to each specific herd

situation.

I can’t emphasize how important it is that everything the newborn calf has contact with should be very

clean. From their arrival in a very clean, well-bedded calving area to well-managed, high-quality

colostrum that is low in bacteria, to properly clean and sanitized feeding equipment and housing, try to

look at every item your calves will come in contact with. The more pathogens that can be removed

through proper cleaning, the more we set our calves up for success.

Another key in calf success is proper nutrition. Calves need a minimum of 8 quarts of either whole milk

or high-quality milk replacer each day to meet their maintenance and growth needs. Their need for

additional energy and nutrition increases anytime the temperature is outside their thermal neutral zone,

particularly when it is colder. (We can help keep calves warmer with a properly fitted calf jacket that

contains a true insulating material, like ThinsulateTM.) Delivering calves ample nutrition with a consistent

temperature, total solids level and on a routine time schedule also aids in prevention.

Housing units, whether individual or group, should be cleaned and disinfected between each use. Calf-Tel offers many plastic feeding and housing options that are designed for easy clean up and can be

viewed at Calf-Tel.com.

All of these factors can be combined to best prevent calf scours. Remember that rotaviruses,

coronaviruses and Cryptosporidium naturally exist on dairy farms. It is our job as the calf caregivers to

limit each newborn calf’s exposure level to these threats. Using a farm-wide approach that includes total

herd health under supervision from a veterinarian, high-quality colostrum management and calf

nutrition, and cleaning and sanitizing all feeding equipment and housing areas gives the best chance of

limiting calf scours events.

Kelly Driver, MBA has been involved in the New York dairy industry all her life. In addition to raising dairy

calves and replacement heifers, she is the Eastern US & Canada Territory Manager for Calf-Tel. Feel free

to contact her at kellydriver@hampelcorp.com with your calf questions or suggest a topic you would like

addressed in a future blog.

Sources:

Armstrong, Joe, DVM. (2019). Causes and prevention of dairy calf scours. University of Minnesota

Extension. Retrieved from Causes and prevention of dairy calf scours | UMN Extension.

Daly, Russ. (2020, September 9). COVID-19 and Livestock: Is there a connection? South Dakota State

University Extension. Retrieved from COVID-19 and Livestock: Is there a connection? (sdstate.edu).

Keha A, Xue L, Yan S, Yue H, Tang C. Prevalence of a novel bovine coronavirus strain with a recombinant

hemagglutinin/esterase gene in dairy calves in China. Transbound Emerg Dis. 2019 Sep;66(5):1971-1981.

doi: 10.1111/tbed.13228. Epub 2019 May 31. PMID: 31077561; PMCID: PMC7168545.

Courtesy of our dealer –

CRI REPRODUCCIÓN ANIMAL

MÉXICO SA DE CV.